חותכן שטוח, חיתוך תרמי, מולטיGRAFOTRONIC

350 200254G

חותכן שטוח, חיתוך תרמי, מולטי

GRAFOTRONIC

350 200254G

VB בתוספת מע"מ

67,500 €

מצב

משומש

מיקום

Kruszyn Krajeński

התמונות מציגות

הצג מפה

נתונים על המכונה

- שם המכונה:

- חותכן שטוח, חיתוך תרמי, מולטי

- יצרן:

- GRAFOTRONIC

- דגם:

- 350 200254G

- מצב:

- מצב טוב מאוד (משומש)

- תפקודיות:

- פועל באופן מלא

מחיר ומיקום

VB בתוספת מע"מ

67,500 €

- מיקום:

- Ceramiczna 15, 86-005 Białe Błota, PL

התקשר

פרטי ההצעה

- מזהה מודעה:

- A18949116

- עדכון:

- עודכן לאחרונה בתאריך 29.12.2025

תיאור

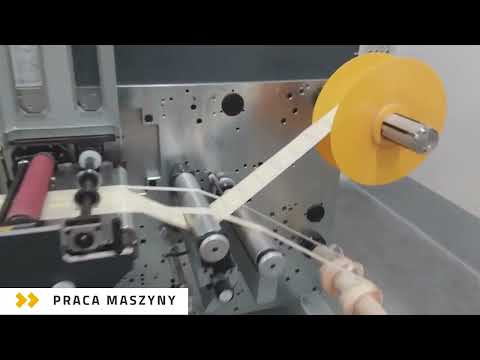

Segment I – Unwinder with stabilizing table

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

Ffodowck U Repfx Af Rju

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

המודעה תורגמה אוטומטית. ייתכנו שגיאות בתרגום.

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

Ffodowck U Repfx Af Rju

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

המודעה תורגמה אוטומטית. ייתכנו שגיאות בתרגום.

ספק

הערה: הירשם בחינם או התחבר, כדי לקבל גישה לכל המידע.

נרשם מאז: 2020

שלח בקשה

טלפון & פקס

+48 52 37... מודעות

ייתכן שגם מודעות אלה יעניינו אותך.

מודעה קטנה

Kaunas

Kaunas

2,792 km

דפוס פלקסוגרפי

MPSEF 330/ 7 color

MPSEF 330/ 7 color

מודעה קטנה

Langenfeld (Rheinland)

Langenfeld (Rheinland)

3,199 km

מכונת הדפסה דיגיטלית

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

מודעה קטנה

Leinfelden-Echterdingen

Leinfelden-Echterdingen

2,920 km

מכונות גרפיות FGT - המרה

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

מודעה קטנה

München

München

2,737 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

מודעה קטנה

Bad Kreuznach

Bad Kreuznach

3,067 km

מכונת דפוס פלקסוגרפית

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

מודעה קטנה

Kaunas

Kaunas

2,792 km

Rewer

Jurmet

Jurmet

מודעה קטנה

Leinfelden-Echterdingen

Leinfelden-Echterdingen

2,920 km

מכונות גרפיות FGT - המרה

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

מודעה קטנה

Leinfelden-Echterdingen

Leinfelden-Echterdingen

2,920 km

מכונות גרפיות FGT - גימור תווית

ROTOFLEXR 1300

ROTOFLEXR 1300

מודעה קטנה

Helmstedt

Helmstedt

3,055 km

מכונת תפירה אוטומטית

Müller Martini3210

Müller Martini3210

מודעה קטנה

Dettelbach

Dettelbach

2,932 km

מערכת כיווץ (מכשיר ריתוך בזווית + מנהרה)

SmipackWS 560 A + T 450

SmipackWS 560 A + T 450

המודעה שלך נמחקה בהצלחה

אירעה שגיאה