מכונת מילוי מים, שמן, סבון, AdBluePROTON EE-ELEKTRONIKA d.o.o

XFR1000

מכונת מילוי מים, שמן, סבון, AdBlue

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

שנת ייצור

2025

מצב

חדש

מיקום

Šašinovec

התמונות מציגות

הצג מפה

נתונים על המכונה

- שם המכונה:

- מכונת מילוי מים, שמן, סבון, AdBlue

- דגם:

- XFR1000

- שנת ייצור:

- 2025

- מצב:

- חדש

- תפקודיות:

- פועל באופן מלא

מחיר ומיקום

- מיקום:

- Krcevina 4, 10360 Soblinec, Hrvatska

התקשר

פרטים טכניים

- רוחב כולל:

- 2,400 מ"מ

- אורך כולל:

- 15,000 מ"מ

- גובה כולל:

- 2,800 מ"מ

- לחץ:

- 8 קורה

- כוח:

- 10.9 קילוואט (14.82 כ"ס)

- משקל עצמי:

- 6,400 ק"ג

- מתח כניסה:

- 400 V

- משקל מילוי (מינימום):

- 200 g

- משקל מילוי (מקסימום):

- 5,000 g

פרטי ההצעה

- מזהה מודעה:

- A17231422

- עדכון:

- עודכן לאחרונה בתאריך 25.09.2025

תיאור

XFR 1000

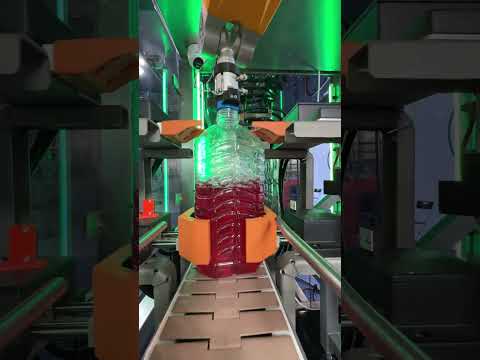

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

Hfsdpfjuq Nv Tsx Abfoc

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

Hfsdpfjuq Nv Tsx Abfoc

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

ספק

הערה: הירשם בחינם או התחבר, כדי לקבל גישה לכל המידע.

נרשם מאז: 2020

שלח בקשה

טלפון & פקס

+385 43 3... מודעות

ייתכן שגם מודעות אלה יעניינו אותך.

מודעה קטנה

Kirchheimbolanden

Kirchheimbolanden

3,049 km

מערכת תיוג למיכלים עגולים ומרובעים

Weidmann Maschinen EtikettiermaschineFL-800

Weidmann Maschinen EtikettiermaschineFL-800

מודעה קטנה

Tata

Tata

2,322 km

מכבש אקצנטרי AIDA NC2-250, 250 טון

AIDA NC2-2502-POINT ECCENTRIC GAP PRESS 250ton

AIDA NC2-2502-POINT ECCENTRIC GAP PRESS 250ton

מודעה קטנה

Niedźwiedź

Niedźwiedź

2,407 km

יחידת מעבה יחידת מדחס

BITZERHSK7461-80-40P

BITZERHSK7461-80-40P

מודעה קטנה

Sonsbeck

Sonsbeck

3,263 km

מכונת בדיקה אוניברסלית לבדיקת מתיחה

Hegewald & PeschkeH5TMCI

Hegewald & PeschkeH5TMCI

מודעה קטנה

Hoofddorp

Hoofddorp

3,401 km

מכונת שקיות נייר תחתית מרובעת מהירה

MASTER BAGMB300X

MASTER BAGMB300X

מודעה קטנה

גרמניה

גרמניה

2,920 km

טורבינת קיטור

Nadrowski BielefeldC4DS-GVI

Nadrowski BielefeldC4DS-GVI

מודעה קטנה

Nether Heage

Nether Heage

3,807 km

מיכל אחסון

Aluminium Bulk Silo21 individual silos

Aluminium Bulk Silo21 individual silos

מודעה קטנה

Jüri

Jüri

3,238 km

פורקן

Valon Kone OYVK-550-Combi 2R/480(620)

Valon Kone OYVK-550-Combi 2R/480(620)

מודעה קטנה

Ostrołęka

Ostrołęka

2,674 km

ייצור חלב ומוצרי חלב

MargoPasteryzator

MargoPasteryzator

מודעה קטנה

Helmstedt

Helmstedt

3,055 km

מדחס בורג 4 בר

KaeserCS 91

KaeserCS 91

המודעה שלך נמחקה בהצלחה

אירעה שגיאה