קו ביקבוק שלם

קו ביקבוק שלם

מצב

משומש

מיקום

Fumane (Verona)

התמונות מציגות

הצג מפה

נתונים על המכונה

מחיר ומיקום

- מיקום המוכר:

- Via Incisa 1, 37022 Fumane (Verona), איטליה

התקשר

פרטי ההצעה

- מזהה מודעה:

- A20007535

- מספר התייחסות:

- LC575

- עדכון:

- עודכן לאחרונה בתאריך 16.09.2025

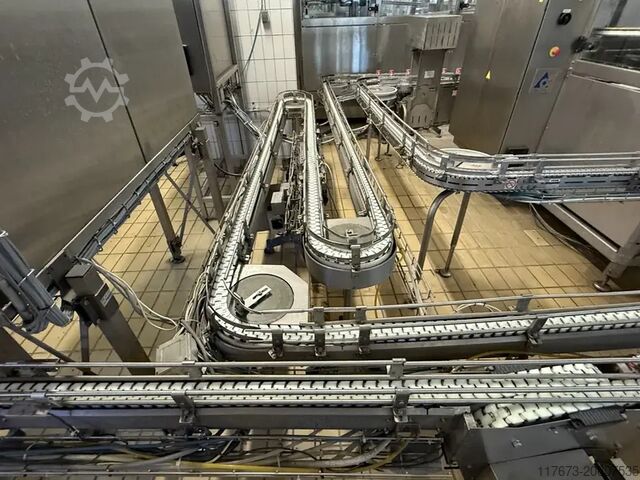

תיאור

Used Tetra Pak Bottling line for UHT Milk 7500 bph, engineered specifically for the aseptic processing and packaging of UHT milk products in 200 ml Slim carton formats. This industrial bottling line consists of original Tetra Pak machinery, including the Tetra Pak TBA/19-30V aseptic filler, integrated with a Tetra Pak automatic conveyor system equipped with Easy Ride accumulation, an automatic straw applicator (TSA 21), and a secondary packaging unit (CBP 70). Each component is engineered for continuous operation and seamless integration, ensuring product safety, operational efficiency, and compliance with international standards for long-life dairy products.

The entire line is built for aseptic processing, managing the forming, filling, closing, accessory application, and secondary packaging of UHT milk in a fully automated sequence. The process ensures high levels of product hygiene, packaging integrity, and line efficiency, supporting industrial-scale operations.

Kdjdpfxjxcwxts Ab Hew

Aseptic Filling Section and Product Handling

At the heart of this line is the Tetra Pak Tetra Brik Aseptic TBA/19 – 30V filling machine, dedicated to producing 200 ml Slim cartons. The aseptic configuration includes a packaging material sterilization process using a hydrogen peroxide (H₂O₂) bath, followed by drying with sterile air. This ensures the complete microbial decontamination of the carton’s internal surfaces before filling.

Filling occurs inside a controlled sterile chamber, which maintains positive pressure isolation from the external environment, guaranteeing the microbiological safety of the UHT milk during packaging. The filling system utilizes a high-precision volumetric dosing head with electronic flow and level control, ensuring consistent, repeatable filling for every package.

Sealing of the carton (both longitudinal and top) is achieved through heat sealing, ensuring tight closure and package integrity. All main mechanical operations are managed by an integrated automation system, which continuously monitors and controls temperature, pressure, and exposure times for each critical phase of the cycle.

Automation, Quality Control, and End-of-Line

This Used Tetra Pak Bottling line for UHT Milk 7500 bph is fully automated via a centralized control panel, with real-time management of all operational parameters for the filler and connected machinery. Each section is equipped with sensors, photocells, safety devices, and operator panels for process diagnostics and fine-tuning. The machines communicate through standardized fieldbus systems and hardwired connections, ensuring perfect synchronization during format changes or start-stop cycles.

Product transport is handled by the Tetra Pak Package Conveyor 21 system, integrated with Easy Ride accumulation. This guarantees smooth handling and continuous alignment of cartons between each stage, providing a buffer of approximately 3 minutes to compensate for minor downstream stoppages and to prevent carton tipping.

The entire line is built for aseptic processing, managing the forming, filling, closing, accessory application, and secondary packaging of UHT milk in a fully automated sequence. The process ensures high levels of product hygiene, packaging integrity, and line efficiency, supporting industrial-scale operations.

Kdjdpfxjxcwxts Ab Hew

Aseptic Filling Section and Product Handling

At the heart of this line is the Tetra Pak Tetra Brik Aseptic TBA/19 – 30V filling machine, dedicated to producing 200 ml Slim cartons. The aseptic configuration includes a packaging material sterilization process using a hydrogen peroxide (H₂O₂) bath, followed by drying with sterile air. This ensures the complete microbial decontamination of the carton’s internal surfaces before filling.

Filling occurs inside a controlled sterile chamber, which maintains positive pressure isolation from the external environment, guaranteeing the microbiological safety of the UHT milk during packaging. The filling system utilizes a high-precision volumetric dosing head with electronic flow and level control, ensuring consistent, repeatable filling for every package.

Sealing of the carton (both longitudinal and top) is achieved through heat sealing, ensuring tight closure and package integrity. All main mechanical operations are managed by an integrated automation system, which continuously monitors and controls temperature, pressure, and exposure times for each critical phase of the cycle.

Automation, Quality Control, and End-of-Line

This Used Tetra Pak Bottling line for UHT Milk 7500 bph is fully automated via a centralized control panel, with real-time management of all operational parameters for the filler and connected machinery. Each section is equipped with sensors, photocells, safety devices, and operator panels for process diagnostics and fine-tuning. The machines communicate through standardized fieldbus systems and hardwired connections, ensuring perfect synchronization during format changes or start-stop cycles.

Product transport is handled by the Tetra Pak Package Conveyor 21 system, integrated with Easy Ride accumulation. This guarantees smooth handling and continuous alignment of cartons between each stage, providing a buffer of approximately 3 minutes to compensate for minor downstream stoppages and to prevent carton tipping.

ספק

הערה: הירשם בחינם או התחבר, כדי לקבל גישה לכל המידע.

נרשם מאז: 2021

שלח בקשה

טלפון & פקס

+39 344 0... מודעות

ייתכן שגם מודעות אלה יעניינו אותך.

מודעה קטנה

Fumane (Verona)

Fumane (Verona)

2,626 km

מכונת מילוי

Tetra Pak®A3Flex

Tetra Pak®A3Flex

מודעה קטנה

Przemyśl

Przemyśl

2,317 km

מכונה לייצור משקאות

TETRA PAK TBA-9 200 SLIMFILLING LINE

TETRA PAK TBA-9 200 SLIMFILLING LINE

מודעה קטנה

הממלכה המאוחדת

הממלכה המאוחדת

3,786 km

כרסומת

2016 Haas DM-2 (VMC)

2016 Haas DM-2 (VMC)

מודעה קטנה

Bury St Edmunds

Bury St Edmunds

3,634 km

גריל חגורה מוטבע

FramptonFG-1-28-P/S

FramptonFG-1-28-P/S

מודעה קטנה

גרמניה

גרמניה

3,179 km

קו צינורות ופרופילים / מפעל לריתוך צינורות

MEER/ SMS MEER/ ELOTHERM

MEER/ SMS MEER/ ELOTHERM

מודעה קטנה

Ystad

Ystad

3,178 km

תרמופורמר

MultivacR-530

MultivacR-530

מודעה קטנה

Großenlüder

Großenlüder

3,018 km

מתקן התזת חול, תא התזת חול

Oliver Fritz GmbH & Co. KGStrahlhaus Easy 10mx5mx5m LxBxH

Oliver Fritz GmbH & Co. KGStrahlhaus Easy 10mx5mx5m LxBxH

מודעה קטנה

Bury St Edmunds

Bury St Edmunds

3,634 km

פורס לבשר וגבינה

Grote613-VS2

Grote613-VS2

מודעה קטנה

Derby

Derby

3,801 km

2010 DFE Meincke, ערבוב Peerless מ-Peerless Forming – תנור DFE Meincke – ...

DFE Meincke, PeeelessMixing from peerless Forming – DFE Meincke Oven...

DFE Meincke, PeeelessMixing from peerless Forming – DFE Meincke Oven...

מודעה קטנה

Italia

Italia

2,320 km

מכונה לייצור משקאות

Bottling Kosme PETBottling Line 5.300 bph

Bottling Kosme PETBottling Line 5.300 bph

המודעה שלך נמחקה בהצלחה

אירעה שגיאה